When to Repair Versus Replace Your Hydraulic Motor

Hydraulic motors are critical in multiple industries for powering equipment like excavators, combine harvesters, conveyors, winches, and more. So, it can be critical to your operations when they go offline. While most common motor issues can be fixed with simple repairs, there may be situations where a replacement is a more cost-effective option.

In this blog, we’ll cover some of the most common issues you’ll experience with your motors, what causes them, and when you should opt for a replacement over a repair.

Common Issues With Motors in Hydraulics Systems

Cavitation

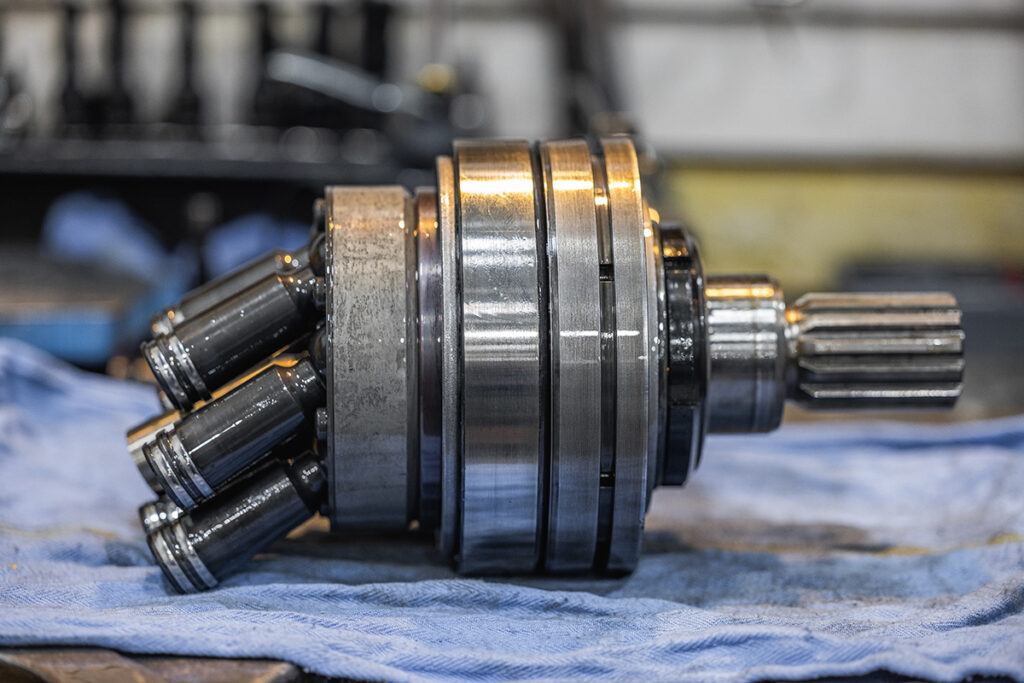

If you hear a sound similar to marbles in a can, it could be cavitation. Visually, you could see pitted or eroded surfaces. Cavitation is caused by excessive vacuum conditions or high temperatures, causing fluid vaporization. While cavitation can be fixed with repairs, if left unresolved for too long, it can damage components beyond repair.

Contamination

If fluid is contaminated by dust or debris, it can cause internal damage in the motor. You’ll often notice unusual performance in your motor, increased wear, and debris in the hydraulic fluid. Usually, contamination can be resolved by cleaning the system and replacing the filters. However, like cavitation, if contamination is left unresolved, it can damage components, and in those situations, a replacement may be needed.

Leaks

Leaks can be easily fixed because they’re commonly caused by seal failure. You’ll notice visible oil outside the motor or a sudden drop in fluid levels. Typically, you just need to replace the seals or tighten connections.

Overheating

Overheating can eventually lead to fluid degradation, which, in many cases, will damage the motor beyond repair. Overheating can happen when your motor is exposed to high ambient temperatures or if it’s run over its rated duty cycle.

Pressure Imbalances

If your motor has trouble reaching full power or operating unusually, you could be experiencing pressure imbalances. These imbalances can happen if the system settings are incorrect or internal components fail. Some pressure imbalance issues can be repaired, depending on the cause. However, if the imbalances are caused by internal motor damage, the entire motor will likely need to be replaced.

Misalignment

Shifting internal components can cause misalignments, manifesting as vibrations or abnormal noise. You may also notice premature wear in your bearings and seals. Internal components can be realigned. However, if the shifting has damaged the internal components beyond repair, they will need to be replaced. Depending on how many internal components need to be replaced, it could be more cost-effective to just replace the entire motor.

Fluid Degradation

If you ever notice dark, cloud, or unusually smelly hydraulic fluid, you need to flush the entire system to remove any residual contaminants, inspect or replace filters and any damaged components, and then add new fluid. Severe fluid degradation may indicate other issues within your system, like your motor overheating, motor connection leaks, or motor wear and tear that’s causing metal particles to contaminate your fluid. Depending on the extent of the motor damage, you may have to replace the entire motor.

Should You Repair or Replace?: Other Factors to Consider

Extent of the Damage

As mentioned earlier, many issues can be repaired if they’re detected early on. Most hydraulic motor issues can be resolved with repairs, such as replacing seals or tightening connections. Generally, leaks, valve sticking, seal swelling or cracking, air entrainment, and fluid contaminations or deficiencies can be repaired. However, if problems like overheating, cavitation, misalignments, and pressure imbalances are left to worsen, components could become so damaged that they’re irreparable.

If you’re not sure how damaged your motor is, we recommend having it inspected by a professional who can help you find the most cost-effective solution.

Age of the Motor & Replacement Part Availability

It can be difficult to find replacement parts for a motor, depending on how old it is. If it’s considered discontinued or obsolete, it might be better to just replace it with a newer model that’s more efficient. This is especially true because, as a motor ages, the progressive effects of stress and degradation can lead to more frequent and costly repairs. It’s also important to note that even if you don’t have an older or discontinued motor, the lead time for obtaining certain parts could impact downtime, so also consider how much time the repair will take and if you can afford to lose that amount of time.

Costs

The cost to repair a hydraulic motor versus replacing it varies widely depending on the extent of the damage and the specific model of the motor. Repairs might be a few hundred dollars for minor issues but can escalate quickly if major components need replacement.

When a repair costs close to 50% (or more) of the price of a new motor, a replacement might be the more cost-effective route.

Think about how many components need to be replaced or repaired, as well as the frequency of repairs that your motor has undergone. Also, think about operational costs—if your motor is constantly being repaired, that significantly impacts your operations. How much downtime can you actually afford? If your motor is constantly offline, it might be time to replace it.

Request an Evaluation Today

The best way to know whether you need a repair or a replacement is by requesting an evaluation, and that’s where Panagon Systems can help.

Founded over two decades ago, we’re an industry-leading manufacturer of aftermarket hydraulic pumps, motors, and replacement parts for brands like Rexroth. All products we manufacture are built in-house in our U.S.-based facility and are thoroughly tested to ensure they meet OEM specifications. In addition to our manufacturing services, we can repair and rebuild hydraulic motors.

Please contact us today to learn more about our capabilities or to request an evaluation.