Types of Hydraulic Pumps

Learn more about the four primary types of hydraulic pumps in this comprehensive guide by Panagon Systems.

Learn more about the four primary types of hydraulic pumps in this comprehensive guide by Panagon Systems.

Hydraulic pumps are critical components of hydraulics systems because they turn electrical energy into fluid power to drive the system. Using the wrong pump can adversely affect the hydraulics system, as the pump cannot provide sufficient fluid pressure. An improperly sized pump will also reduce a hydraulic system’s performance and power, eventually leading to overheating. […]

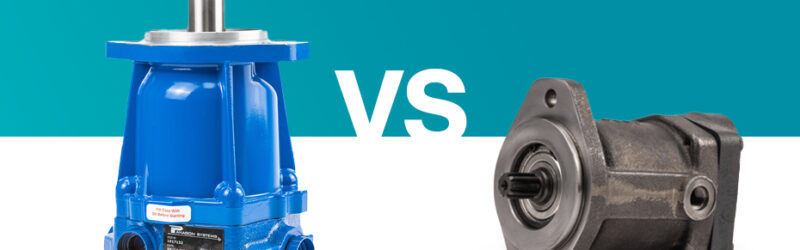

What is the differences between fixed and variable displacement hydraulic pumps, and how do you choose the best option? Read on to learn more.

Hydraulic pumps are critical components within hydraulics systems that generate liquid flow by converting mechanical energy to hydraulic or fluid energy. Scheduled maintenance and regularly looking for signs of failure help to prevent premature failure and costly repairs. In this blog post, we’ll cover the common signs of hydraulic pump failure and considerations when choosing […]

Are you curious about hydraulic pump systems, what they are, and how they’re used? In this article, we explain the basics of hydraulic systems, the many types of systems, how they work, and best practices for taking care of them. What Is a Hydraulics System? A hydraulics system uses compressed fluid to transfer an applied […]

A two-stage hydraulic pump uses two pumps to generate high and low liquid flow rates and high and low pressure without requiring higher power consumption. A low-pressure, high-rate inlet valve and a high-pressure, low-flow rate outlet valve allow the pump to generate higher oil pressure at a lower or higher flow. Common Uses Two-stage pumps […]

Manufacturers like Panagon Systems rely on reverse engineering to ensure quality. Reverse engineering is the process of identifying a product’s design as it was originally manufactured. It is called reverse engineering because you start the process with an already-manufactured product and end it with design blueprints. Reverse engineering is a less costly and often faster […]

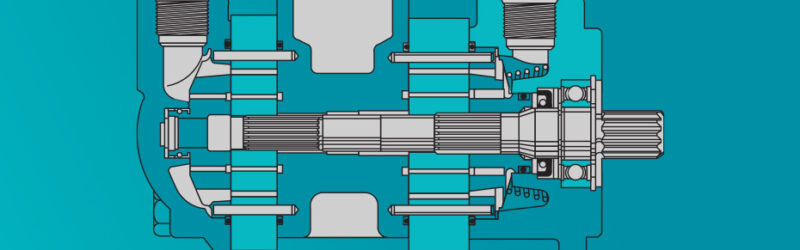

Hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. They’re known for their high efficiency and are commonly used in high-pressure applications. There are also two major types of hydraulic piston pumps: axial and radial; both can have fixed or variable displacement; fixed displacement means that the pump is delivering the same amount […]

Replacing a failing hydraulic pump can be challenging. If the wrong alteration is made, you risk damaging your entire hydraulics system. Furthermore, there are many reasons why your pump may be failing, but not all of them may require a full replacement. If your hydraulic pump isn’t working like it used to, you need to […]

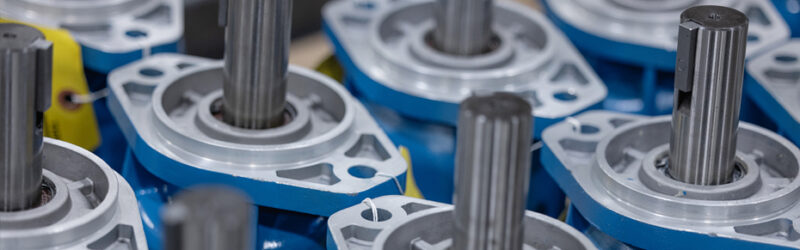

Our manufacturing facility houses many CNC machines capable of producing high-quality hydraulic components and replacement parts.

Contact