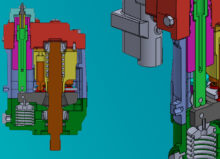

Danfoss Pumps: Replacement Parts Guide

Danfoss hydraulic pumps can be found in many industrial applications, from agricultural machinery to construction equipment, and are well-loved due to their reliability, efficiency, and high performance.

However, despite the pumps’ durable design, regular maintenance and timely replacement of worn parts are essential to sustaining efficiency and performance.

In this article, we’ll explore some of the most common wear parts in Danfoss pumps, including signs and causes of wear.

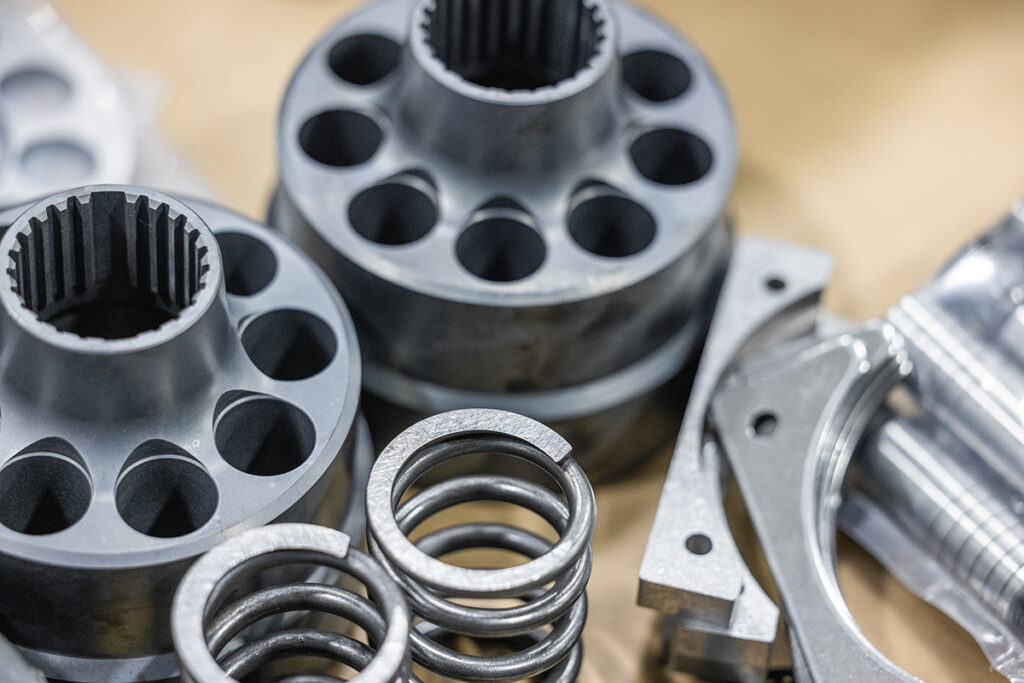

Cylinder Block

The cylinder block helps facilitate piston movement; it often needs to be replaced due to wear from constant friction and exposure to high-pressure conditions. The most common sign of cylinder block wear is scoring or grooving on the surface, which leads to decreased efficiency and potential system failure.

Valve Plate

The valve plate directs the flow of fluid between the pump’s inlet and outlet and often operates under constant stress. It typically experiences wear from fluid abrasion and thermal degradation. Unaddressed wear on the valve plate can eventually lead to cracks, erosion, and eventual leaks. When inspecting the valve plate, look for scoring on the surface.

Swashplate

A swashplate controls the stroke length of the pistons and directly influences the pump’s displacement and overall performance. Like the valve plate, the swashplate operates under significant stress, eventually leading to wear from the constant friction, deformation, and fatigue cracks. Signs of swashplate wear include visible scoring, cracks, or excessive play. Although they generally have a long service life, they should still be inspected regularly and replaced as needed based on operational conditions and wear signs.

Input Shaft

The input shaft transfers rotational energy from the power source to the pump mechanism; this component often experiences wear due to constant rotation, misalignment stress, and material fatigue. If you notice abnormal noises and vibrations, check the input shaft for signs of wear (scoring and grooves).

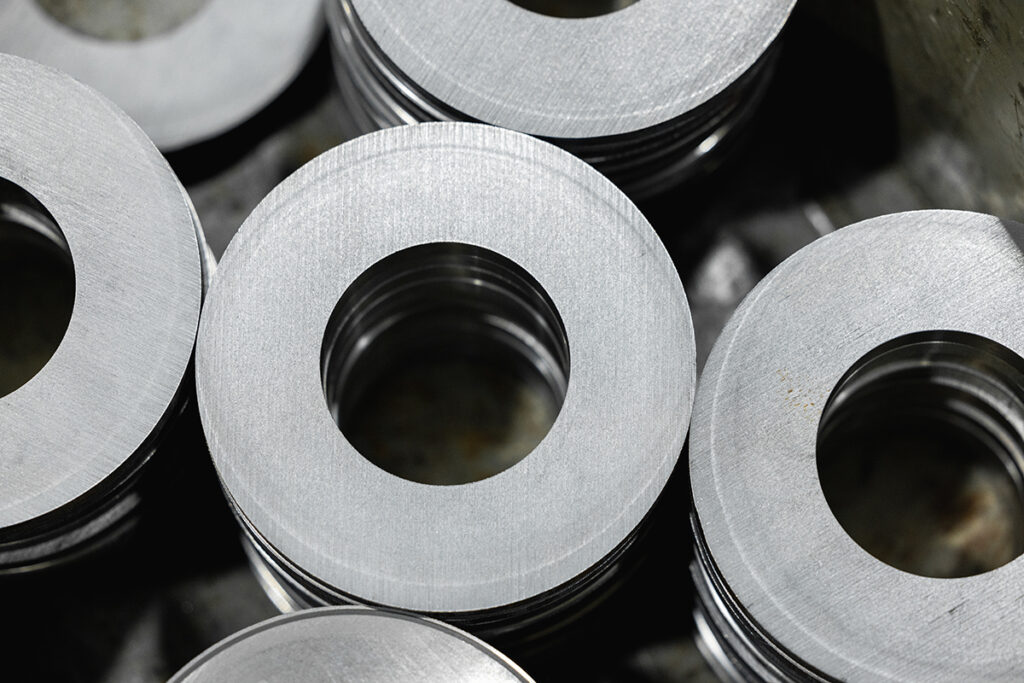

Displacement Piston

A displacement piston directly influences the pump’s output flow and pressure. It can experience wear from abrasive contaminants in the fluid, mechanical fatigue, and damage from overheating. If you notice scoring on the piston’s surface, reduced movement efficiency, and leaks around the piston, you probably need to replace it.

Adjustment Rod

If you have a variable displacement pump, you’ll need to regularly inspect the adjustment rod for signs of wear. Repeated adjustments, corrosion, and mechanical damage can all cause wear and eventual failure in an adjustment rod. If you’ve noticed stiffness in the road during operation, irregularities in pump performance when adjustments are made, or visible corrosion or grooves, a replacement is needed.

Bearings

Bearings, like roller and ball bearings, are some of the most common wear items in a pump. They frequently require replacement due to wear from continuous operation (especially in heavy-load applications), contamination in the hydraulic fluid, or improper lubrication. Signs of bearing wear include unusual noises, excessive vibration, decreased pump efficiency, and increased heat generation. When performing daily inspections, also look out for metal debris in the oil.

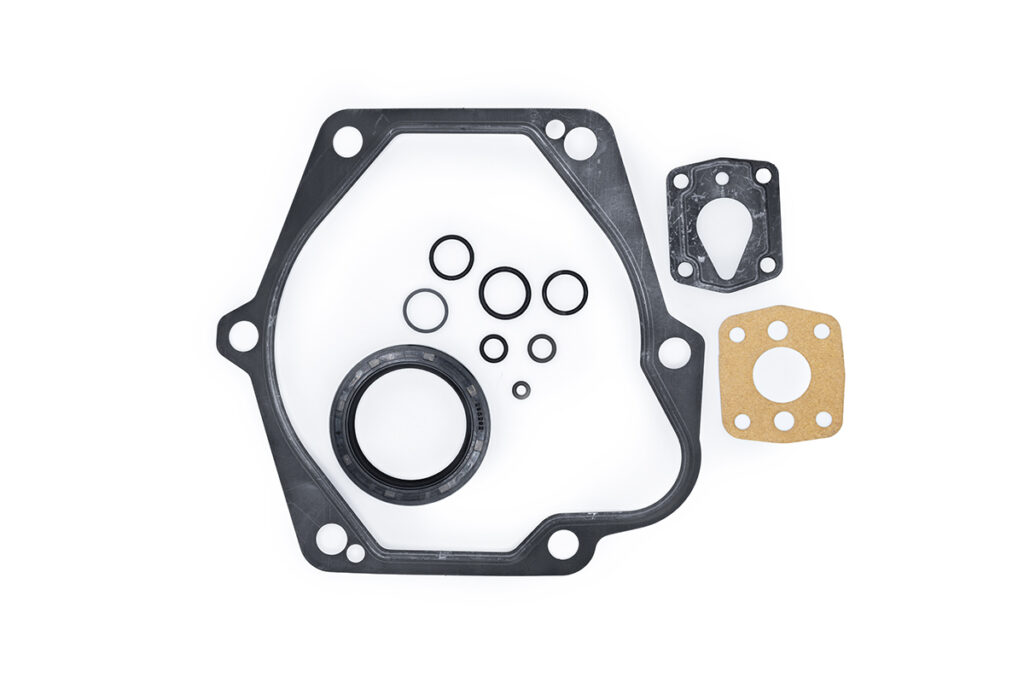

O-rings, Gaskets, & Seals

Similar to bearings, O-rings, gaskets, and seals may need to be regularly replaced based on operation conditions to ensure the hydraulics system remains leak-free and maintains pressure integrity. O-rings, gaskets, and seals are typically made from rubber or other elastomeric materials and experience wear from friction, degradation from heat and chemical exposure, or eventual hardening or cracking over time. If you see visible cracks in the seals and/or gaskets during inspection, replace them. Other potential signs of gasket/seal damage include fluid leakage and loss of pressure.

Relief Valve

The relief valve allows excess fluid to bypass back to the reservoir or through a return line when pressures exceed preset values, ensuring the system’s pressure remains within safe limits. Repeated cycling, contamination, and spring fatigue can all cause wear on this component. If you’ve noticed that the relief valve cannot maintain pressure, continuous leakage, or unusual noises, check the valve for physical deformation (warping or cracking), noticeable wear or scoring on the valve seat, and corrosion or buildup.

Housing

Lastly, you may eventually have to replace the housing or the case that houses the pump’s internal components. Over time, the housing may crack due to stress or impact, corrode from harsh operating environments, or experience wear from constant vibration. You’ll know that the housing needs replaced if you see visible cracks and leaks where it joins with other components.

Generally, the housing doesn’t need replacing as often as some of the other components listed in this article. However, if it’s exposed to continuous vibration, corrosive environments, extreme temperature fluctuations, or is used in high-pressure applications, you should perform visual inspections more often on the pump’s housing.

When Should You Replace the Entire Pump?

Replacing an entire pump may be more cost-effective than individual parts in some scenarios. These scenarios include:

- Your application has changed, and you need to upgrade your pump to meet new operational demands.

- The cost of replacing multiple worn or damaged parts approaches or exceeds the cost of a new pump.

If you’re unsure if you need to replace components, upgrade/retrofit your pump, or order a complete replacement, contact our professionals at Panagon Systems.

Get Danfoss Pump Replacement Components From Panagon Systems

Panagon Systems is a trusted manufacturer of OEM-equivalent Danfoss piston pumps. We also manufacture and sell reliable replacement parts for most Danfoss piston pumps and can provide pump repairs and potential engineering recommendations for upgrades/retrofits.Please contact us today if you need help ordering replacement components or a replacement pump, troubleshooting issues with your pump, or starting a rebuild or upgrade.