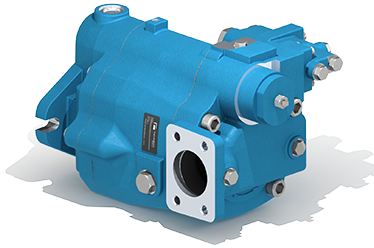

A Guide to Discontinued Vickers/Eaton Hydraulic Piston Pumps

Hydraulic pumps are critical components of hydraulics systems because they turn electrical energy into fluid power to drive the system.

Using the wrong pump can adversely affect the hydraulics system, as the pump cannot provide sufficient fluid pressure. An improperly sized pump will also reduce a hydraulic system’s performance and power, eventually leading to overheating. So, it’s vital that you choose the right pump type and brand.

Among all the piston pump brands on the market, Vickers/Eaton is one of the most reliable brands. However, certain models will become obsolete over time, making it harder to find high-quality replacements.

Panagon Systems is a trusted manufacturer of aftermarket hydraulic piston pumps and motors from brands like Vickers/Eaton. Some discontinued piston pumps we manufacture include those in the PVM, PVB, PFB, PVE, PVH, and PVQ series.

Keep reading to learn more about each Vickers hydraulic piston pump we manufacture, including key features and specifications, to help you make the best selection.

PVM

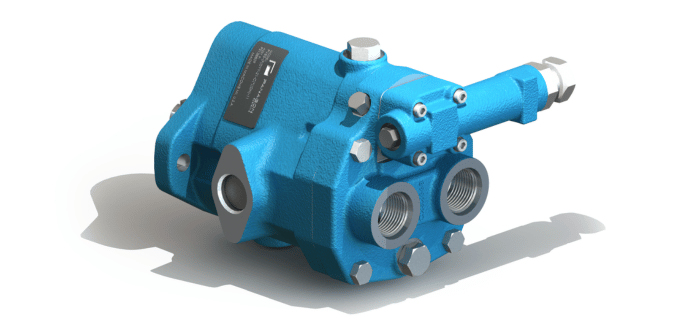

A render of the PVM98 model

The PVM pump is a variable displacement pump with an open circuit, axial design. As a variable displacement pump, it can alter the fluid pressure and volume depending on which equipment or machinery it is powering. These highly efficient pumps are designed for quiet operation, have minimal maintenance requirements, and feature adjustable ports and high-quality saddle-type yokes.

Specifications

Specifications vary based on the specific model within the PVM series. View specification ranges below:

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 1.1 in3 (18 cm3) to 8.60 in3 (141 cm3)

- Maximum Operating Speed: 1,800 RPM (2,800 RPM With High-Speed or “M” model)

- Weight Ranges: 33 lbs (15 kg) to 145 lbs (66 kg)

- Temperature Rating: 180 degrees Fahrenheit (82 degrees Celsius)

- Recommended Fluid Viscosity Range: 160 to 40 cSt (83 to 187 SUS)

Key Features

These robust, well-manufactured piston pumps reduce operating costs, mount in numerous configurations, and run on various industrial hydraulic fluids.

Additional features include:

- Bell-shaped housing and bimetal timing plate to improve pump filling, reduce sound, and extend pump life

- Multiple port locations allow for multiple configurations

- Strong, durable, robust shaft bearings reduce maintenance and upkeep costs

- Reduced system shock via low-pressure ripple

Common Applications

- Mining, Oil & Gas, & Injection Molding Machines

- Metal Cutting Equipment & Machinery

- Large Industrial Conveyor Lines

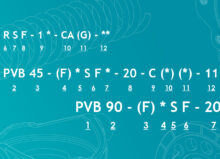

PVB

A render of the PVB 5 model

The PVB line is a series of high-performance axial piston pumps with variable displacement. All pumps within the PVB series are drive-ready and highly efficient.

Specifications

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 0.64 in3 (10.55 cm3) to 12 in3 (197.50 cm3)

- Drive Speed: Up to 3,600 RPM

- Weight Ranges: 18 lbs (8 kg) to 211 lbs (104 kg)

- Maximum Output of Torque: 354 lbf inch (40 Nm) to 1,408 lbf inch (159 Nm)

Key Features

- Can run on various hydraulic fluids

- Adjustable pressure compensator and limiter

- Features a load sensor compensator and handwheel

Common Applications

- Small Hydraulic Presses

- Metal Injection Molding (MIM)

- Plastic Injection Molding

- Conveyor Lines

PFB

The PFB fixed displacement pumps are highly regarded for their volumetric efficiencies and have similar features as their PVB/variable counterparts.

Specifications

There are three different pumps within the PFB series. Each of their specifications is outlined below.

PFB 5

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 0.64 in3 (10.55 cm3)

- Weight: 11 lbs (5 Kg)

- Maximum Shaft Speed: 3,600 RPM (With Anti-Wear Hydraulic Oil)

PFB 10

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 1.29 in3 (21.10 cm3)

- Weight: 22 lbs (10 kg)

- Maximum Shaft Speed: 3,200 RPM (With Anti-Wear Hydraulic Oil), 1,800 RPM (With Water-in-Oil Emulsion), and 1,800 RPM (With Water Glycol)

PFB 20

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 2.61 in3 (42.80 cm3)

- Weight: 42 lbs lbs (19 Kg)

- Maximum Shaft Speed: 2,400 RPM (With Anti-Wear Hydraulic Oil)

Key Features

- Lightweight, durable, and affordable

- Excellent volumetric efficiency

- A simple and effective design that increases reliability and results in fewer replacement parts

- Reduced risk of leakage thanks to SAE straight-thread and four-bolt flange ports

Common Applications

Because these are fixed displacement pumps, the PFB pump models are ideally suited for high-speed, high-powered applications requiring a fixed flow rate, including:

- Oil Lubrication Systems

- Conveyors

- Agricultural & Farming Equipment

- Manufacturing Equipment & Machinery

PVE

Eaton’s discontinued PVE (“E Series”) inline pumps have variable displacement and are available in three different displacement sizes, providing users with the ultimate flexibility. Displacement is varied and controlled by pressure and flow compensators. The PVE line is also lightweight but highly durable, thanks to its aluminum housings.

Specifications

The specifications for each PVE model are outlined below.

PVE12

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 1.54 in3 (25.2 cm3)

- Maximum Speed: 3000 RPM

PVE19

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 2.50 in3 (41 cm3)

- Maximum Speed: 2,400 RPM

PVE21

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 2.75 in3 (45.1 cm3)

- Maximum Speed: 2,400 RPM (0 psig Inlet Pressure)

Key Features

- Thru-drive available on PVE 19 and PVE21 models

- Displacement is controlled by pressure and flow compensators for maximum flexibility

Common Applications

PVE pumps are ideal for various applications, including:

- Skid Steer Loaders

- Wheel Loaders

- Road Planers

PVH

PVH pumps are compact, lightweight, high-flow, and high-performance with variable inline displacement.

Specifications

Specifications vary across multiple models within the PVH series. A summary of the range of these specifications is provided below:

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 3.5 in3 (57.4 cm3) to 8 in3 (131.1 cm3)

- Maximum Speed: 1500 RPM (With Zero Inlet Pressure) to 1800 RPM (With Zero Inlet Pressure)

- Weight Range for Basic Models: 79 lbs (36 kg) to 145 lbs (66 kg)

- Typical Flow: 22 GPM (102 LPM) to 49 GPM (185 LPM) (at 1500 r/min)

Key Features

- 95%-plus volumetric efficiency

- Extremely quiet

- Multiple drive shafts and control options

- Thru-drive arrangements

Common Applications

These efficient pumps are designed for extreme industrial applications and have multiple compensators for optimal control. Common applications include:

- Construction

- Machine Tools

- Plastics Machinery

PVQ

Vickers/Eaton’s PVQ (“Q”) series of inline variable displacement piston pumps are known for their quiet operation, compact design, and high efficiency, even when operating in the most challenging environments.

Specifications

Specifications vary across all nine models. A summary of the range of these specifications is defined below:

- Operating Pressure: 3000 PSI (210 Bar)

- Displacement Per Revolution: 0.643 in3 (10.5 cm3) to 2.75 in3 (45.1 cm3)

- Maximum Operating Speed: 1800 RPM

- Input Power (at Max Pressure and Rated Speed): 10 HP (7.4 kW) to 38 HP (28.3 kW)

- Weight: 16 lbs (7.2 kg) to 45.4 lbs (20.6 kg)

Key Features

- Compact design

- Compatible with most types of hydraulic fluid

- Thru-drive configuration available

- Multiple control and mounting options

- Patented timing arrangement for reduced noise

Common Applications

PVQ pumps have a wide range of applications, including:

- Small Presses

- Shears

- Machine Tools

- Plastic Injection Molding Machines

- Metal Injection Molding Machines

- Conveyor Lines

Considerations

Selecting the right pump comes down to defining your specific application. For example, running a single piece of equipment at a fixed flow rate means you’ll need a fixed displacement pump, like a PFB pump. If your application requires that the displacement change, a variable pump will provide more versatility and efficiency.

Other considerations include the hydraulic pressure you’ll need the pump to support, the operating temperature, how frequently you’ll run the hydraulic system, space restrictions, mounting requirements, and speed

- Flow Rate Requirements (Fixed Versus Variable)

- Pressure Requirements

- Operating Temperature

- Frequency of Use

- Space Restrictions

- Installation/Mounting Requirements

- Speed Requirements

Get Help Selecting Your Piston Pump

For more than two decades, Panagon Systems has become the go-to resource for companies looking for aftermarket hydraulic piston pumps, motors, and replacement components from trusted brands like Vickers/Eaton.

Contact us today if you have questions about our replacement pumps or need help finding the best solution for your application—we can even customize specific models based on your unique needs and requirements.