Hydraulic Pump for Dump Trailer

Hydraulic pumps have many benefits when it comes to unloading the heavy loads that dump trailers must haul on a regular basis. Hydraulic systems are easy to operate, and a pump seldom runs dry with proper maintenance. But, the real benefit of a hydraulic pump for dump trailer system is the power these pumps can deliver.

Dump trailers get the greatest amount of power density from hydraulics when compared to other mechanical power transmission systems. This means, even the smallest hydraulic actuator can handle more force and power than a comparable electric or fuel-powered pump.

Hydraulic pumps for dump trailers are used to lift the truck’s trailer bed from the frame. Even though these pumps are workhorses and typically give many years of useful service, there are ways to extend the life of your dump trailers.

How to Extend The Life of Your Dump Trailers?

A dump trailer is a costly investment that will generally bring a full return when used consistently and maintained properly. And as in all mechanical systems, it is the moving parts of your dump trailer that wear out first. Here are some ways to extend the life of your dump trailer:

Top off fluids – Keep all fluids at their full levels and make sure all moving parts of the dump trailer are properly lubricated. You want to avoid dry hydraulic and lube conditions that will metal-to-metal damage. Also, make sure low fluid levels are not due to hydraulic pump leaks or hose seepage.

Keep strainer clean – Your pump’s strainer filter keeps coarse material out of the hydraulics system, but they themselves can become clogged. Remove any particles or debris from the strainer to improve the system’s efficiency and to prevent further damage to the pump for the dump trailer.

Performing regular inspection and maintenance, which includes:

- bleed the air out of the lines occasionally

- repair seals and hoses that are torn or dry

- follow the manufacturer’s specs for operating pressure

What Are the 4 Types Of Hydraulic Pumps?

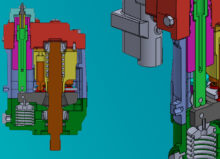

A dump pump is the type of hydraulic pump used for dump trailers. These pumps are not suited for continuous duty. They work by building pressure then releasing it through an assembly that features a three-way directional control valve.

Gear Pumps are the most common design, having fewer moving parts. These fixed displacement pumps will force oil through the system with each rotation of the pump’s shaft.

Piston Pumps create power by displacing oil through the system by the action of a piston and can handle higher pressures than gear pumps.

Vane Pumps feature a rotating shaft that forces oil to be picked up and displaced between the vanes of the pump to build pressure and generate power.

Clutch Pumps are small, belt-driven, displacement pumps with an electromagnetic clutch.

How Do I Know If My Hydraulic is Bad on my Dump Trailer?

The first sign that the hydraulics pump on your dump trailer is bad is when the pump does not run at all. This is a total failure and will typically result in replacing the pump on your dump trailer. But, if the pump runs and the trailer doesn’t go up or down, then the hydraulics system does not have enough power to activate fluid solenoids that will activate the up and down valves.

Other signs that your hydraulic pump for a dump trailer is going bad include:

- Increased noise or heat is being generated

- Hydraulic cylinders have slowed down motion

- Hydraulic oil leaks around or inside the system

- The seals need replacing often

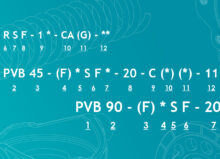

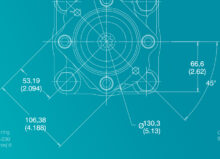

Visit us at Panagon Systems to learn more about our full line of hydraulic pumps, motors, and parts for a variety of industrial and mobile applications. Panagon Systems has been producing hydraulic parts on demand for a number of shops, manufacturers, and industries for over 25 years.