The Hydraulic Pump Rebuild Process

If your hydraulic pump is acting more like a squeaky wheel, it might be time for an overhaul. Pressure drops, leakage and other signs of pump failure can become chronic and cause costly downtime and repairs. It may save you time and money, in the long run, to rebuild the pump.

As the largest aftermarket hydraulic piston pump manufacturer, Panagon Systems is uniquely qualified to diagnose and remedy your pump problems. When we perform a hydraulic pump rebuild, our replacement pumps function comparably to brand-new products. We are the only North American pump manufacturer that consistently produces quality OEM-grade replacement pumps.

Identifying the Problem

If you are unsure what your pump needs, your eyes and ears are your best tools. Unusual noises, such as knocking sounds or vibrations, can be clues to a failing component. Fluid leaks and erratic temperature or pressure readings can indicate a seal malfunction and require further investigation by our technicians.

Finding Expert Help

Unusual sights and sounds don’t always call for a hydraulic pump rebuild, but they do indicate something in the hydraulic system needs to be addressed. Our technicians are here to help you sort that out. Once you decide to let us help, we will take the lead and begin designing a rebuild strategy that accomplishes your goals and works within your budget.

Cleaning and Disassembling

When your pump arrives at our rebuild facility, our hydraulic specialists prepare it for inspection and evaluation. We clean the exterior first and then begin taking it apart, piece by piece. It’s important each component be cleaned thoroughly using an industrial parts washer. Our technicians will perform an initial visual scan to get an idea of the scope of your hydraulic pump rebuild.

Inspection and Evaluation

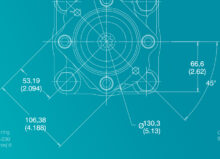

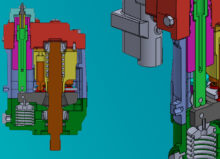

You might be surprised at how many parts comprise a hydraulic pump. Their design can be complex. Our specialists carefully inspect every component of your pump – each O-ring, valve, filter and seal – for wear and tear or damage. The parts used for your rebuild must be in top condition. Those that pass our screening with flying colors may be reused. Parts that fail the screening will either be reconditioned or remanufactured. A meticulous inspection generates crucial data needed to design a successful plan for your hydraulic pump rebuild.

Rebuild Planning

Panagon’s hydraulic specialists have seen it all when it comes to pumps, and we leave no stone unturned in creating a blueprint for your project. We make sure you receive an analysis of your pump’s condition, a detailed cost breakdown and recommendations for how to minimize future pump wear and tear.

Reassembly and Testing

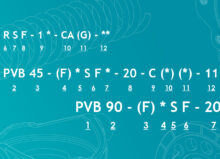

A Panagon pump rebuild generally involves a combination of reused and newly manufactured parts. We use state-of-the-art computer numeric control machines to manufacture many of our precision replacement parts. Once the pump is carefully reassembled, we subject it to a multi-point testing regimen and return it to you in like-new condition.

The Panagon Difference

If you are in the market for a hydraulic pump rebuild that rivals new products, such as the Eaton/Vickers and Rexroth lines of new piston pumps, you are in the right place. With nearly 25 years of experience, Panagon teams are equipped to deliver a product that meets your specifications, your budget and your schedule. We know we’ve done our job when your equipment is at its best and your clients are satisfied.

Panagon Systems’ extensive inventory of hard-to-find pump components fills an important void in the industry. Our affordable hydraulic pump rebuilds have proven their value with scores of Panagon customers. We hope you will allow us to work with you to put your squeaky-wheel pump problems in the rear-view mirror. It’s our business to help you succeed.