Identifying Rexroth Replacement Pump Parts

Rexroth piston pumps are incredibly durable and reliable, but over time, you may have to replace several components, especially if your pump is in a corrosive environment, exposed to excessive vibration, or in an application with frequent start-stop cycles.

Common “Wear” Parts

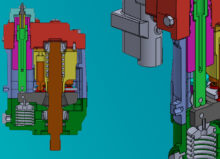

There are many parts of your pump that could wear out over time, primarily due to their function. These include:

- Pistons & Piston Rings: These two parts experience constant motion and pressure, which leads to more wear over time.

- Cylinder Bores: The inside surface of the cylinders can wear out due to friction with the pistons.

- Valve Plates: Because they help regulate fluid flow, valve plates are subjected to high-pressure differentials, which can cause potential cavitation over time.

- Swashplate: This is a common wear component specifically for variable displacement pumps. The swashplate controls piston stroke, so it can wear out due to the constant contact it has with the piston.

- Bearings: Bearings often wear out frequently, especially under high-pressure conditions or if the pump is subjected to excessive vibration. Contaminants, like dirt or moisture, can also cause abrasive wear and/or corrosion on the bearings.

- Seals & O-rings: These parts will degrade over time due to heat, pressure, and fluid contact.

- Springs: It’s common for springs, especially those in control mechanisms, to lose tension or break.

- Ball Guides & Slipper Pads: Like most of these parts listed here, ball guides and slipper pads typically wear out from constant motion.

- Control Valves: Control valves can wear out from repeated cycling.

When finding replacements for worn components, it’s crucial that you find parts that are compatible with your specific pump. Just buying replacement parts without doing any research increases the risk of wear, leaks, contamination, cavitation, overheating, and other issues that ultimately impact your pump’s performance.

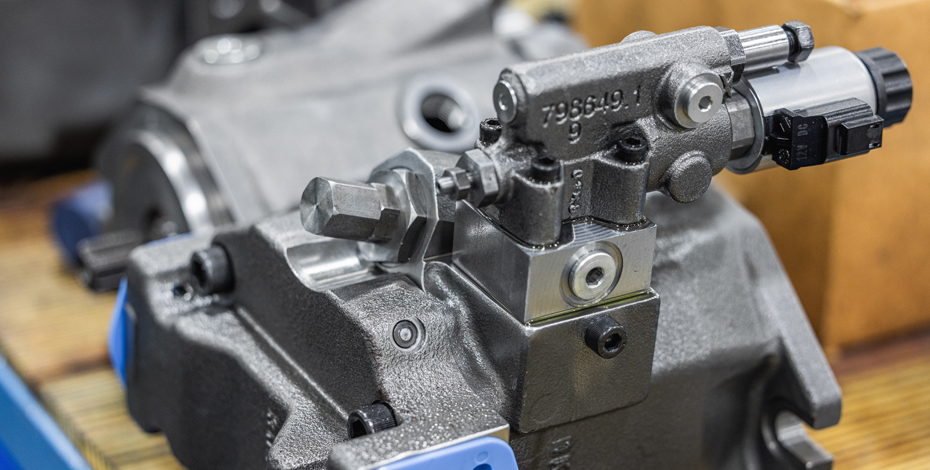

The challenge is that there are many Rexroth pumps on the market. Unfortunately, even if you disassemble your pump, it’s rare that you’ll find part numbers listed on the components themselves. The good news is that locating your pump’s model number can help you start the process of finding replacement parts.

Find Your Pump’s Model Number

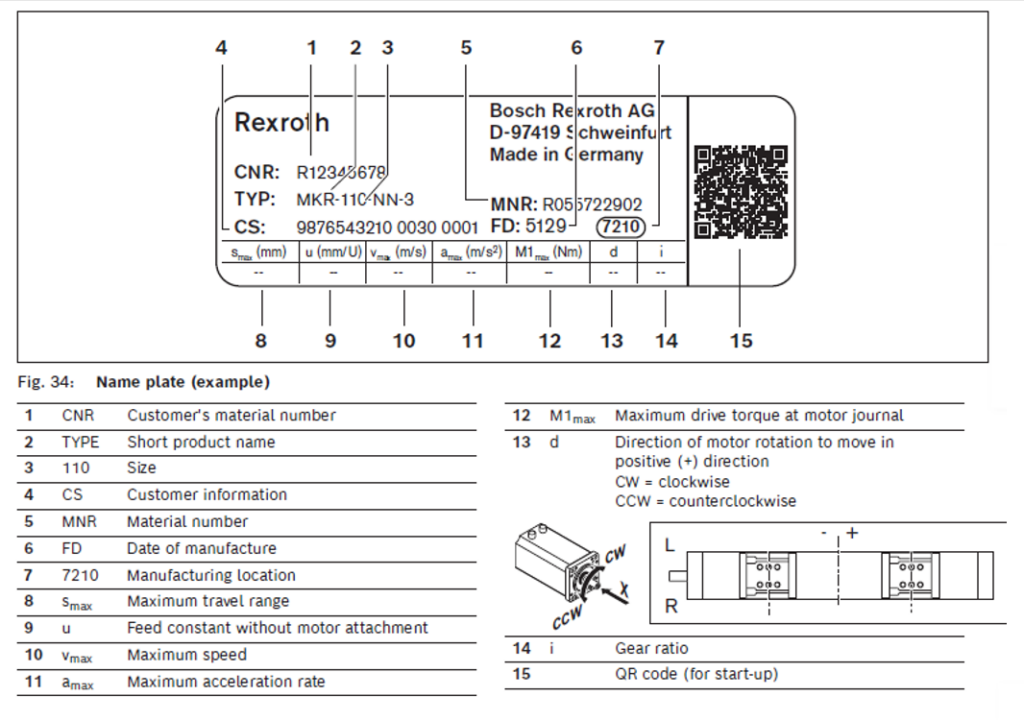

You can easily find the model number by looking at your operator’s manual. If you’ve lost that manual, the model number can be found on the nameplate of your pump. Most Rexroth pumps have a nameplate or data plate attached to the body. This nameplate contains the short product name/model number (also called material designation), the serial number (also called customer information), the material number, which identifies what types of materials were used when manufacturing the pump, and the date the pump was manufactured.

What Model Numbers Can Tell You

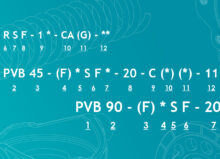

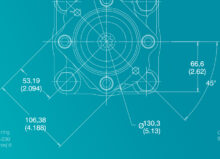

Rexroth model numbers are long and typically contain a mix of letters and numbers. These numbers and letters contain important information about the pump, including its type and specifications, such as displacement, pressure rating, and control type.

So, in a model number like A10VSO45DFR1/31R, the ‘A10VSO’ indicates the product family (A10) and design (axial piston variable pump). The ‘45’ indicates its size (45 cm3), and ‘DFR1’ refers to its control device (DR F controller). You don’t necessarily need to know the full model breakdown and what each letter and number combination means, but you at least need to know your pump’s design and the product family it belongs to.

In some situations, a letter might be at the end of the model number to indicate that a particular material is used for the pump’s seals. For example, Viton seals are commonly used for high-temperature applications, so some model numbers might incorporate a ‘V’ at the end of the number to indicate that that particular model uses Viton seals. You may also see ‘N00,’ the standard for NBR/nitrile seals.

Find Your Pump’s Serial Number

The serial number and model number are on your pump’s nameplate/data plate. The serial number on a Rexroth nameplate is located below the short product name with the initials’ CS’ next to it.

The serial number is different from the model number and can, in some situations, be more helpful for a technician than the model number. There is only one serial number per pump, so service technicians can learn more about your pump’s specific configuration, production history, service history, whether it’s still under warranty, and whether there are any recalls or recommended upgrades.

Consult Your Manual or the Manufacturer’s Website

As a general rule of thumb, if you can’t find part numbers, consult your operator’s manual or the manufacturer’s website. Although you’ll still need to know your pump’s model number, both the manual and the manufacturer’s website should have information about replacement parts.

If you don’t have a manual and are searching Rexroth’s website instead, type in the product family (designation), model number, or serial number into the search bar, and you’ll be given a list of options. When you click on one of the results, you’ll be given the option to download a spare parts list that includes a complete component breakdown diagram. The downside is that you will need an account with Rexroth to view more details about specific spare parts.

Another issue you may run into is the parts being discontinued or no longer available, depending on how old your pump is. In these situations, you’ll need to either contact a Rexroth service technician or consider purchasing aftermarket parts.

Aftermarket Versus Direct OEM Replacements

Direct OEM replacements often seem like the best choice because the same manufacturer makes them, so you know that quality won’t be an issue. However, the downside is that direct OEM replacements are often more expensive and have long wait times, resulting in more downtime if you don’t have loans for your offline equipment.

Comparatively, aftermarket parts are less expensive and will ship faster. When you buy aftermarket parts, look for companies like Panagon Systems that offer OEM equivalents so you don’t have to worry about variations in quality.

Get Replacement Rexroth Pump Parts From Panagon Systems

Founded over 25 years ago, Panagon Systems is an industry-leading manufacturer of OEM-equivalent Danfoss, Rexroth, and Caterpillar piston pumps, motors, and replacement parts. All components we manufacture are produced in-house in the United States, thoroughly inspected to ensure they meet OEM specifications, and backed by an 18-month warranty for your peace of mind.

Visit our website today to search for parts by OEM part number, model number, series number, and part type, or contact us for assistance.