The Value of Vickers Vane Pumps

Vickers is a leading global provider of industrial hydraulic products. Owned by the Eaton Group Fluid Power division, this brand sells some of the best vane pumps on the market.

Vane pumps are the perfect solution for manufacturers seeking high pumping efficiency and low noise. These pumps are ideal for many industrial and automobile applications. And they feature modular designs that make them very easy to work with.

How a Vane Pump Works

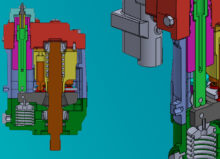

Vane pumps feature a rotor that consistently turns vanes inside a cavity, and the rotation of the vanes pushes fluid through the pump. Typically, vane pumps (including Vickers models) are used for liquid, but they can also be designed for gases.

Common Applications

Vickers manufactures several lines of vane pumps that are used in applications, including molding, earthmoving, construction, manufacturing, material handling, and civil engineering. Some are also used in oil and gas, transportation, utility, and even entertainment.

Vickers’ Vane Pumps

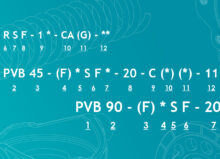

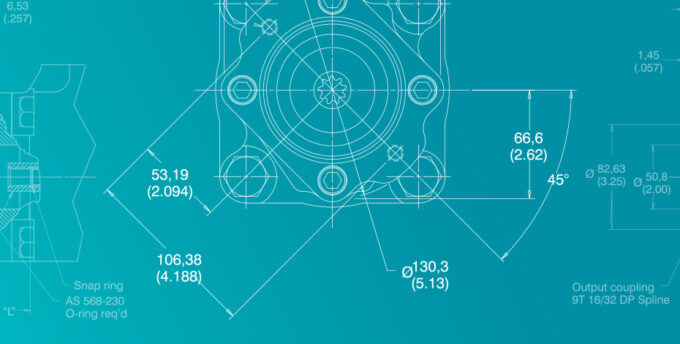

Vickers’ vane pumps can be grouped into two main categories: single-vane and double-vane. Both types work similarly, but single-vane pumps feature a more simple design. As its name suggests, single-vane pumps have a single suction and pressure stage per rotation, while double-vane pumps have two suction and two pressure actions per rotation.

Vickers also designs their vane pumps with a cartridge kit system that allows for greater interchangeability and repair.

Some of their top-selling vane pumps include:

- V Series: These pumps offer strong performance with very low noise. They are known for their long service lives and excellent serviceability. V series pumps feature a 12-vane design, making them the perfect option for indoor applications and other uses that require reduced noise.

- V10 and V20: For industrial applications, a pump offering high performance may be necessary. The V10 and V20 pumps are used as pilot and auxiliary pumps in a variety of complex systems. These vane pumps are commonly used to manufacture trucks and buses.

- VQ & VQH: These two pump series share the intra-vane cartridge design with the V series. They are ideal for medium- to high-pressure uses. With a 10-vane architecture, they can offer strong volumetric efficiency and serviceability. The VQH series is especially well-suited for high pressures.

- VMQ: If you need a vane pump for the highest-pressure applications, you need the VMQ series. These Vickers pumps can provide higher pressure than any of the others. They also achieve surprisingly low noise levels for such high pressure.

Benefits of Choosing Vickers Vane Pumps

- Good Performance: Vickers pumps offer impressive performance at various pressure levels. They can be counted on for reliable and robust operation.

- Small Size: Many vane pumps in the Vickers line are available in surprisingly small packages. Additionally, they are modularly designed, making them easy to fit even in tight applications.

- Well-Suited for Low-Viscosity Fluids: Vane pumps excel at moving low-viscosity fluids. They can even be run dry for brief periods without damage.

- Low Noise & Vibration: Vickers pumps provide very low noise, making them ideal for vehicles and heavy equipment applications. The low noise and vibration make them easier and more comfortable to operate.

- Excellent Serviceability: Finally, they are very easy to service. Most of the parts are easy to swap out, and several series of pumps have cartridge designs for fast maintenance.

Get Vickers Pumps & Replacement Parts from Panagon Systems

Do you need help selecting the right pump for your application? Reach out to Panagon Systems today. We specialize in manufacturing aftermarket Vickers/Eaton hydraulic pumps. We also sell and manufacture all types of pump replacement parts.

If you have questions about our capabilities or need help selecting a pump, please contact us today.