When to Replace a Pump Coupling?

Couplings fail for many reasons. The most common is misalignment, which puts excessive stress on the flexible component of the assembly. Other causes include vibration, shock loading, and corrosion or chemical attack.

Depending on its design and the materials it’s made from, a flexible pump coupling should last between two and eight years. Elastomeric couplings typically have shorter lives, while metal disc-pack couplings usually last longer. However, delaying replacement until failure is a bad idea because it usually leads to unplanned equipment downtime, expensive repairs, and expedited ordering, and could even damage the pump.

Couplings could be replaced as part of routine preventive maintenance (PM), which risks spending more money and incurring more downtime than necessary. A more pragmatic approach is to conduct regular inspections and schedule replacement when it’s starting to become necessary.

Signs of Impending Failure

If inspections are to be part of the PM routine, it’s important to know what to look for. Signs that it’s time to consider replacing a pump coupling include:

Excessive Vibration

Look for abnormal or unusual levels of vibration in the entire motor-pump assembly, and consider using vibration monitoring sensors on critical pieces of equipment to determine a baseline from which changes are readily detected.

Vibration often results from an out-of-balance condition, which may deteriorate the coupling. However, it could also come from the motor, drive system, or the pump itself. Whatever the source, vibration signifies a problem, especially if it’s increasing in intensity.

Unusual Noises

Unusual noises are more common with elastomeric couplings than metal. Listen for grinding, clicking, or rattling sounds coming from the coupling as it rotates, which indicate that an internal component has failed or that parts are rubbing together.

With pumps that run intermittently, listen for noises at start-up and shut down. Clicking, tapping, or knocking sounds indicate some play within the coupling that will almost certainly get worse over time.

Visible Damage to the Coupling Elements

Look for signs of tears or splits in the polymer with elastomeric couplings. With other coupling types, examine the assembly carefully for signs of damage. Note that inspection must be done with the drive shut down and the coupling not rotating. Depending on the space available, a mirror may also be needed to inspect the entire surface.

Misalignment Between the Pump & Y Motor Shafts

Angular and parallel misalignment may be obvious at the coupling, particularly as it rotates. Other signs to look for are:

- Cracks and tears caused by excessive flexing.

- Dust under the coupling, resulting from excessive wear.

- High temperature (color changes can show when a coupling has been running hot, but you can also use a small thermal camera or non-contact temperature probe).

Lubricant Leaking Around the Coupling Area

Wear in a coupling can allow lubricant to escape. If you notice evidence of oil or grease on or under the coupling, you need to examine it closer.

Dealing With Problematic Couplings

Whenever a coupling shows signs of impending failure, a replacement should be scheduled as soon as possible. If a new part is not on the shelves, one should be ordered immediately.

Not changing the coupling risks a failure that will put the pump out of action and possibly damage the motor/drive system and/or the pump, resulting in unplanned equipment downtime.

Preventing (or Delaying) Failure

Even when coupling replacement is scheduled, it takes time and incurs costs. That’s why it’s prudent to extend coupling life as long as possible. You can prevent and/or delay failure by:

- Following the manufacturer’s instructions when installing new couplings.

- Minimizing angular, parallel, and axial misalignment between the drive and the pump.

- Ensuring the coupling is sized correctly in terms of dimensions, maximum torque, and intermittent/continuous duty cycle.

- Ensuring the pump never operates beyond its design specifications.

- Providing shielding or a guard when the coupling is in an exposed position.

- Making regular inspections part of the PM regimen for the pump.

- Lubricating the coupling according to the manufacturer’s recommendations and including this in the PM schedule.

Additionally, if a coupling fails repeatedly after a relatively short period, conduct a problem-solving or continuous improvement exercise to determine the reasons and identify any changes needed.

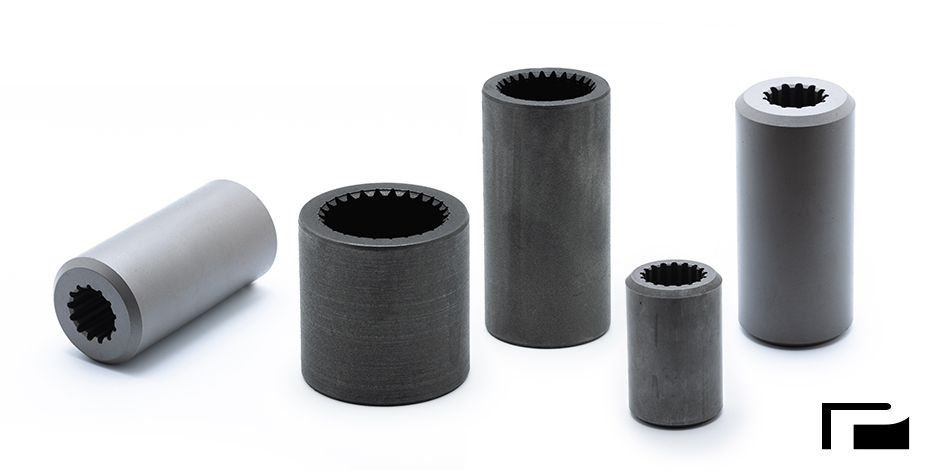

Tips for Selecting a Coupling

Always start by following manufacturer’s recommendations. These recommendations are developed from their experience and intimate knowledge of the equipment and will usually provide the longest service life.

However, if the manufacturer’s recommendations are not available or the coupling is failing prematurely and needs upgrading, factors to consider are:

- Motor torque and/or horsepower

- Shaft speed

- Misalignment

- Physical size/space available

- Operating environment (especially temperature and the potential for corrosive fluids)

Get Help Finding a Replacement

Sourcing replacement parts like pump couplings can be challenging, especially when makes and models are unknown or obsolete.

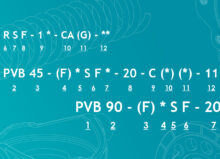

If you’re dealing with a situation like this, talk to our experts at Panagon Systems. Our mission is to supply customers with the hydraulic components they need to keep critical equipment running.

We specialize in manufacturing OEM-equivalent replacement parts for Danfoss/Eaton/Vickers and Rexroth hydraulic pumps and motors. We also build complete pumps, assembled, tested, painted and shipped from our U.S.-based facility in Michigan. Whether you need a specific replacement part or a source for a family of pumps or motors, we can help. Contact us today to learn more.